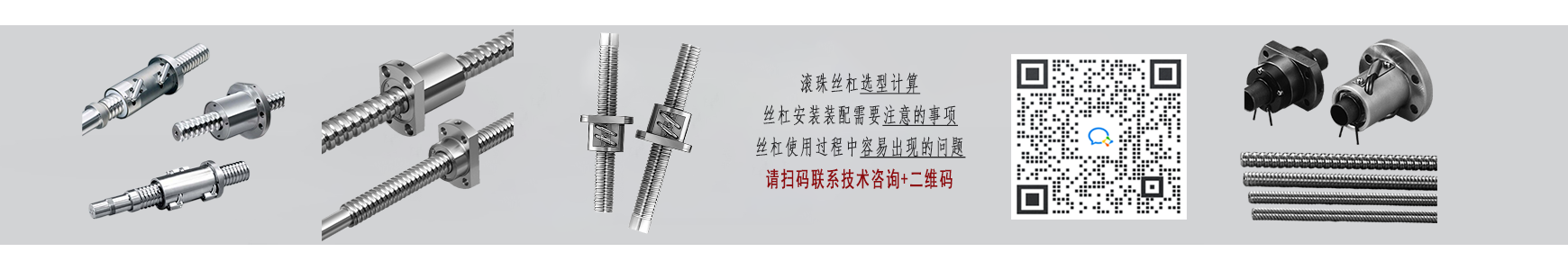

河南滚珠丝杠精度等级的分类标准是什么? 是否有售后服务?,5. 产品的品质和性能如何,是否有质量保证?,9. 维修中心提供哪些售后服务?,9. 滚珠丝杠的扭矩估算与滚珠的大小有关吗?,6. 这种连接方式的制造工艺是怎样的?,5. 浙江滚珠丝杠的应用对产品性能有何影响? ,7. 该模组的使用寿命有多长?,8. 如何判断双光轴滚珠丝杠是否损坏或故障?,6. 它适用于哪些应用场景?,9. 滚珠丝杠两端轴承的价格是多少?

来源: | 发布时间:2023-07-01 01:08:08

河南滚珠丝杠的精度等级通常为C3、C5、C7和C10。其中,C3精度等级为最高,其误差范围在0.01mm以内;C5精度等级为中等,误差范围在0.015mm以内;C7精度等级为次之,误差范围在0.02mm以内;C10精度等级为最低,误差范围在0.03mm以内。不同精度等级的滚珠丝杠适用于不同的场合,一般来说,精度要求高的场合需要选择精度等级较高的滚珠丝杠。

相关问题:

注塑件的强度是否足够支持滚珠丝杠螺母的应用?

1. 准备工具和材料:滚珠丝杠、卡簧、扳手、螺母、垫片、油脂等。 2. 将滚珠丝杠放置在工作台上,将卡簧放在滚珠丝杠的两端,确保卡簧与滚珠丝杠的槽位对齐。 3. 按照滚珠丝杠的安装方向,将垫片放置在滚珠丝杠的一端。 4. 将滚珠丝杠插入要安装的机器中,确保滚珠丝杠的方向正确,并将螺母旋紧。 5. 检查滚珠丝杠的旋转是否灵活,如有卡顿或不顺畅的现象,应重新拆卸并检查。 6. 在滚珠丝杠的两端涂上适量的油脂,以保证滚珠丝杠的正常运转。 7. 最后,将机器的上盖盖好,完成滚珠丝杠的安装。在注塑件中,会用到哪些材料来制造滚珠丝杠螺母?

滚珠丝杠螺母可以用注塑件制造,但是需要考虑注塑件的材料和强度是否能够满足使用要求。一般来说,使用工程塑料或者增强材料注塑制造滚珠丝杠螺母可以得到良好的效果,但是需要进行严格的测试和验证。此外,注塑件的制造成本相对较低,可以在一定程度上降低制造成本。

龙岗滚珠丝杠螺母具有高精度、高承载能力、高刚性等特点,广泛应用于数控机床、精密机械、航空航天等领域,

3. 滚珠在滚动通道中不断滚动,将转动的动能转化为线性运动的动能,从而推动螺母沿着螺纹轴线性移动,

2. 食品级润滑脂:适用于食品加工设备等需要满足卫生标准的场合,符合FDA标准,Ball Screw A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. Design Ball screws consist of a screw, nut, and balls that operate similarly to bearing components. The screw has a precision ground or rolled helical groove acting as the inner raceway for the ball bearings. The nut, which is mounted on the carriage or housing, contains the ball bearings. The balls roll between the screw and nut to minimize friction. This design allows ball screws to operate at higher speeds and with greater accuracy than conventional lead screws. Advantages Ball screws offer several advantages over conventional lead screws, including: • Higher efficiency • Lower friction • Higher accuracy • Higher speed • Longer life • Lower maintenance • Better repeatability • Reduced wear and tear Applications Ball screws are used in a variety of applications, including: • Machine tools • Robotics • Aircraft and aerospace applications • Medical equipment • Semiconductor manufacturing • Solar panel manufacturing • Packaging machinery • Printing presses • Automotive manufacturing • Material handling equipment Conclusion Ball screws are precision linear actuators that offer several advantages over conventional lead screws, including higher efficiency, accuracy, speed, and life. They are used in a variety of applications, including machine tools, robotics, and aerospace applications. Proper selection, installation, and maintenance are critical to ensuring optimal performance and longevity.,滚珠丝杠是一种采用滚珠来传递负载的机械元件,其特点是具有高精度、高刚性、高速度和高效率等优点,

5. 调整滚珠丝杠的前后间隙,使其能够自由转动,并且能够保证x轴的运动平稳,重载变位机滚珠丝杠是一种用于传递动力和运动的机械元件,在电机内,滚珠丝杠通常用于将旋转运动转换为直线运动,用于控制电机的位置和速度,伊春锡青铜滚珠丝杠升降机是一种使用锡青铜滚珠丝杠作为传动装置的升降机,主要用于物品的升降、搬运和存储等工作,1. 直径:通常为6mm至80mm不等;

2. 导程:通常为1mm至50mm不等;

3. 线数:一般为2至10线不等;

4. 精度等级:高精度、普精度、粗精度等级;

5. 材质:常见的材质有GCr15、9Cr18、SUS304等;

6. 长度:根据用户需求定制,长度一般为1m至6m不等;

7. 加工方式:常见的有冷轧、热轧、磨削等